phone:联系人:

13714630748(白先生)

18124150753(王先生)

屏幕修复专线:13145848466(潘生)

fax:0755-85279156

mailbox:ckdseiki@126.com

address:Meicheng Industrial Park, Langjing Road, Dalang Street, Longhua District, Shenzhen

You are here: Home >Application Solution > Laser glass cutting

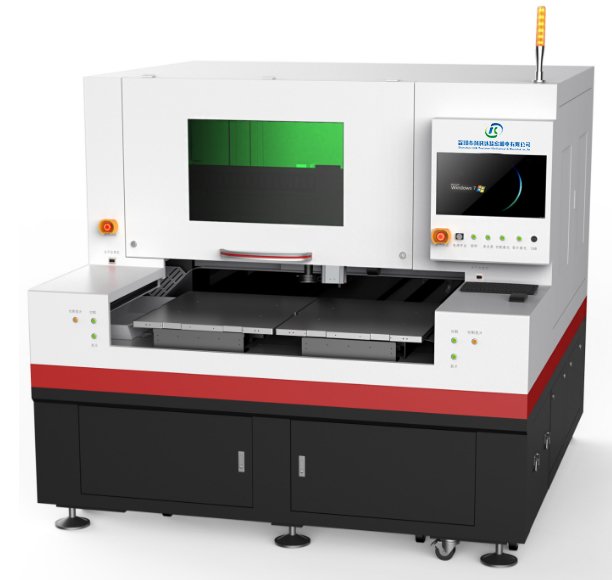

Since 2010, we have been focusing on the research and development, production and sales of laser and its supporting products. After repeated research, we strive to break through. The brittle material without taper picosecond laser cutting machine produced has solved all the above problems at one time.

Equipment advantage

Compared with CNC processing equipment, brittle materials have no taper picosecond laser cutting machine, no consumables in the production process, high production efficiency (cutting speed up to 500mm/s, several times the processing efficiency of CNC), which saves manufacturing costs for processing manufacturers and improves product profits. Chuangkeda has a professional team of laser and automation industry R & D and design for more than ten years. The equipment design uses high-quality imported durable parts, and the long-term production of equipment is stable and reliable.Compared with traditional cutting methods, the advantages of this equipment are as follows:

Large cutting thickness: achieve a knife cut 19mm thickness of white glass (15mm thickness of a knife, and mass production in the client so far)

High efficiency: the cutting speed can be as high as 500mm/s, several times the processing efficiency of CNC, and dozens of times that of water knife. No secondary processing, small edge breakage, no washing, grinding, polishing and other secondary processing

Smooth and flat, no damage: the edge is neat, good vertical, no micro-cracks, broken or debris

High edge strength: three times that of traditional cutting methods

Environmental protection without consumables: no contact cutting, energy saving and environmental protection

Cutting precision ≤20µm, can flexibly achieve all kinds of glass abnormity cutting

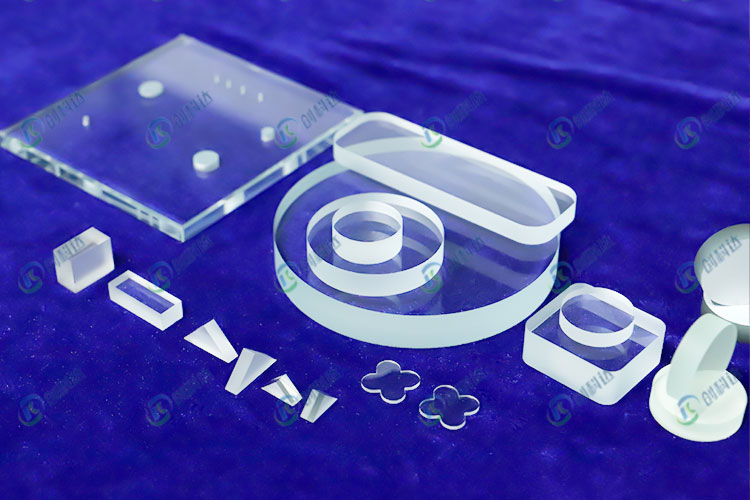

Product specific application

1, reinforced and non-reinforced glass cutting, such as: car Windows, mobile phone glass cover, car glass cover, camera glass cover, etc.;2, sapphire glass cutting, such as: mobile sapphire cover plate, camera sapphire glass cover plate, sapphire light strip (LED light strip);

3, other optical glass cutting, such as: filter cutting, mirror cutting, etc.;

Product design performance characteristics

1. The light source is a high-power picosecond laser, and the core devices such as the core seed source are provided by international first-line manufacturers, and the use is stable;

2, autocratic glass cutting head, the lens is imported from the United States, the spot is fine, the focus is long, the minimum focus spot is <2um, the focal depth length can reach 19mm;

3, the motor platform, optical platform base using natural marble, after two fine grinding processing, accuracy level reached 00;

4, X/Y axis motor adopts high-end linear motor, Germany 0.1um digital grating ruler, Taiwan screw and guide rail, high-quality core moving parts, 24-hour operation without fault;

5, the use of high negative pressure vacuum pump adsorption products to ensure positioning stability;

6, device alignment CCD and telecentric vision lens, accurate identification of circle, cross and other Mark points;

7, the electrical components are made of Schneider, the switching power supply is made of Taiwan Mingwei;

8, the cutting software is powerful, supporting the cutting of segments in one piece, separate cutting, separate segments, through the left and right platform side of the start button operation, flexible and convenient (such as: left platform cutting, right platform fragmentation; Left platform cutting segments, right platform cutting, etc.);

9, breakthrough to achieve 19mm thickness glass across the board.

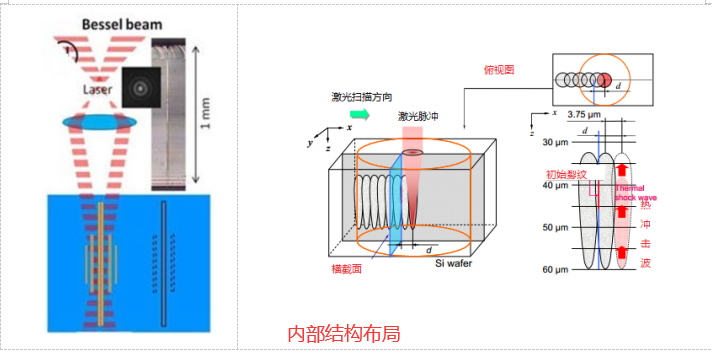

Principle of equipment processing

Sample display